Ultra-Smooth, Optically Clear, & Quantum Ready Polishing

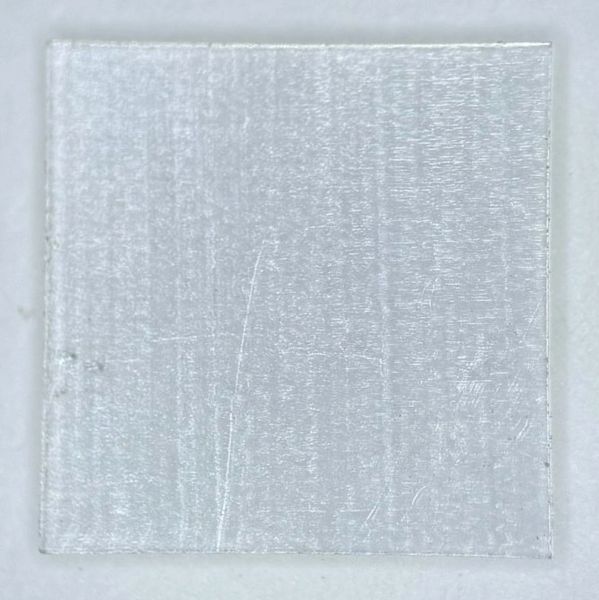

Diamond substrate prior to polishing, with heavy etching clearly visible across the entire face. The surface is clouded, uneven, and optically rough. This surface appearance is typical after a diamond has been laser cut and has yet to undergo surface polishing.

Such a finish is not suitable for quantum or photonic applications, as the surface irregularities introduce:

- High optical scatter and light loss

- NV center instability and reduced spin coherence

- Poor bonding interface performance

- Unreliable photon emission uniformity

The etched texture disrupts both optical clarity and atomic-level smoothness, making this surface unsuitable for high-precision qubit, sensing, or photonic integration work until it undergoes controlled polishing and surface reconstruction.

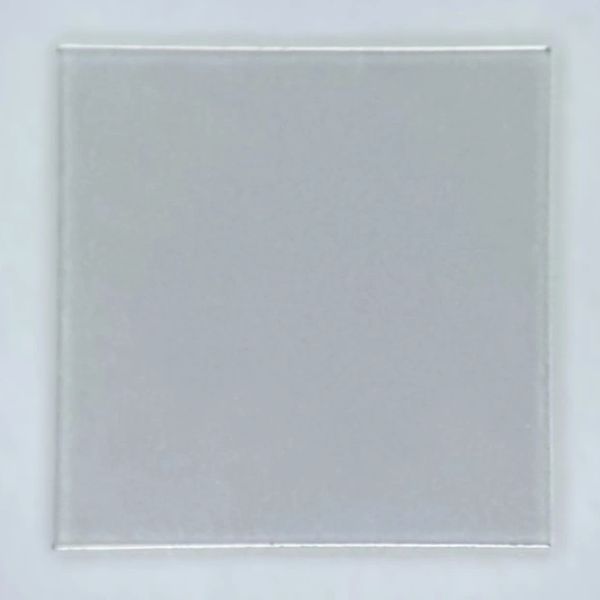

In this post-polish image, the diamond substrate surface has been fully restored to a smooth, optically clear, and uniform finish. All etching artifacts, micro-pits, and haze have been removed, resulting in a surface that is clean at both the visual and atomic scale.

The final surface roughness measures below 0.8 nm, placing it firmly within quantum-grade tolerances for NV center formation, single-photon emission, device bonding, and photonic integration. This level of refinement eliminates scatter pathways, supports long spin coherence stability, and ensures reliable optical coupling.

This finish represents the highest polish class we offer—completely flat, distortion-free, and suited for the most demanding diamond-based quantum and photonic applications.

LEARN MORE ABOUT OUR CAPABILITIES BELOW...

Polishing to meet Your Requirements

Ultra-Smooth Quantum Surface Performance

Polishing to meet Your Requirements

- Surface Etch Removal

- clean-up pass to stabilize surface and remove chemical or laser etching damage

- reduced haze, subsurface stress mitigation, improved bonding surfaces

- Material Thinning – controlled reduction down to 0.150 mm while maintaining structural integrity

- Premier Quantum Finish – advanced atomic-level polish for optical and NV-based applications. Surface roughness results below 0.8nm

Flexible Polishing Capacity

Ultra-Smooth Quantum Surface Performance

Polishing to meet Your Requirements

- One-sided polishing to full 6-side finishing

- Multi-facet and custom polishing options

- Ideal for substrates, plates, chips, and custom dimensions

- Supported for Single Crystal CVD, HPHT, electronic-grade, and optical-grade diamond

Ultra-Smooth Quantum Surface Performance

Ultra-Smooth Quantum Surface Performance

Ultra-Smooth Quantum Surface Performance

- Sub-nanometer finish available with our premier process

- Measured roughness as low as 0.7 nm Ra

- Consistent profile repeatability of 0.8 nm

- Superior flatness for high-stability photonic coupling and chip-level device assembly

Application Areas

Fast Turnaround Without Compromise

Ultra-Smooth Quantum Surface Performance

- Quantum computing diamond nodes

- NV sensing arrays / magnetometry platforms

- Single-photon emission devices

- Integrated photonic cavity and waveguide alignment

- Diamond MEMS, chip bonding & hybrid assemblies

- Advanced spectroscopy and optical metrology

Quantum & Photonic Applications

Fast Turnaround Without Compromise

Fast Turnaround Without Compromise

Achieve quantum-grade surface preparation with precision diamond polishing engineered specifically for research, quantum sensing platforms, photonic integration, and next-generation solid-state qubit development.

Fast Turnaround Without Compromise

Fast Turnaround Without Compromise

Fast Turnaround Without Compromise

- Most polishing orders completed in just a few days

- Scalable for single-piece research substrates or production-run polishing

Diamond Substrate Polishing

Copyright © 2025 AccuPoint Diamond, LLC - All Rights Reserved.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.